Each product finds in the logistics system the spaces necessary for its proper management.

Thanks to important investments Chiaravalli Group has over the years developed areas dedicated to each of its products in order to combine quality with a 360° service that starts from technical consultancy and reaches the possibility of configuring and customizing the product according to the needs of the customer.

The new facility is designed to meet the specific needs of our customers while improving our capabilities and speeding up delivery times.

Our primary goal in creating this assembly area was to increase the number of mounting desks, allowing us to work on more projects simultaneously and reduce lead times. By doing so, we can better serve our customers and meet their demand for faster and more efficient production.

We also took into consideration the well-being of our workers, as we aim to improve their efficacy and reduce fatigue. Our new assembly area features ergonomic workstations, optimized lighting, and advanced technology to reduce physical strain and improve productivity.

Our commitment to customer satisfaction is at the heart of everything we do at Chiaravalli Group spa. By investing in this new assembly area, we are not only improving our own capabilities but also demonstrating our commitment to meeting our customers' needs.

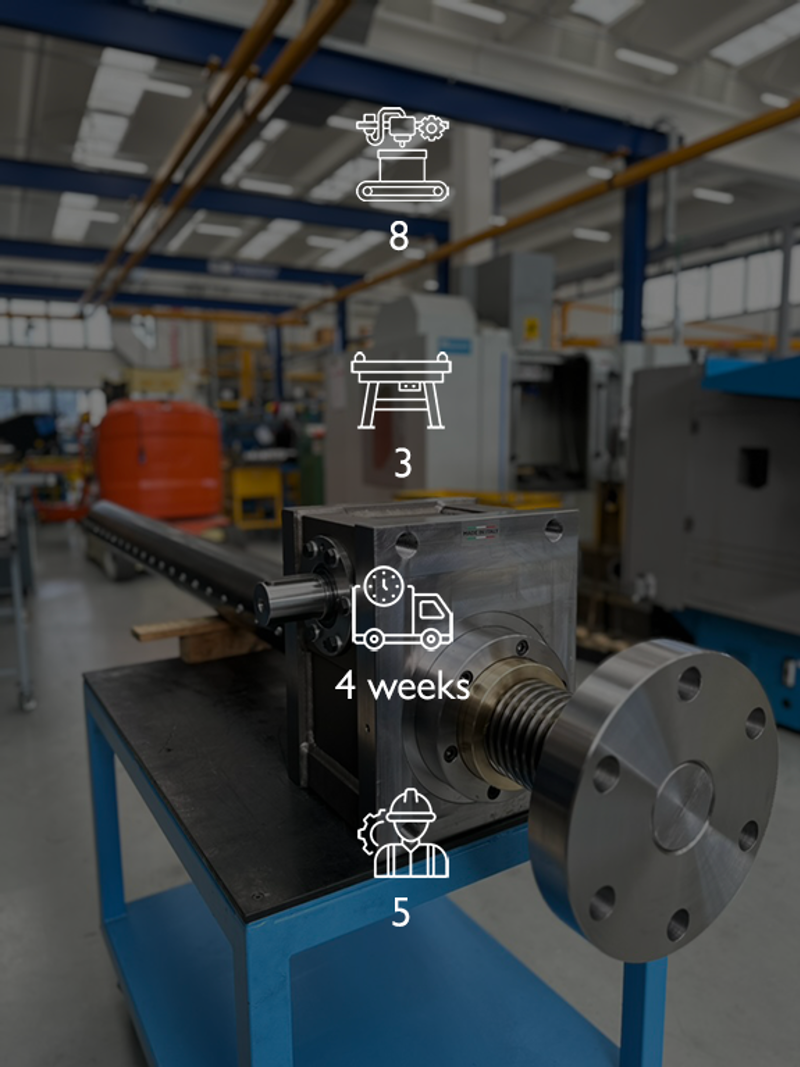

The new mounting area for mechanical worm screwjacks is the result of extensive research and development by our team of experts. It has been specifically designed to offer a more efficient and effective solution for mounting mechanical worm screwjacks, ensuring that our customers can benefit from the most reliable and high-quality products.

Our new mounting area has been developed with the goal of improving the speed of delivery for this product, ensuring that our customers receive their orders as quickly as possible. By optimizing our production process, we have been able to significantly reduce lead times, making it easier for our customers to get the products they need when they need them.

In addition to improving delivery times, our new mounting area also provides our team with access to a wider range of tools and capabilities. This means that we can offer even more advanced and specialized solutions to our customers expanding the range of services we provide.

Our mounting area for automatic tensioners has been developed to offer a more efficient and effective solution for mounting automatic tensioners, ensuring that our customers can benefit from the most reliable and high-quality products.

One of the key benefits of our new mounting area is the ability to satisfy the specific needs of our customers. By offering customizable products, we can provide automatic tensioners that meet the unique requirements of our customers. This allows us to offer solutions that are not only technically superior but also visually appealing, making them ideal for a wide range of applications.

Another important feature of our new mounting area is the ability to quickly deliver different types of automatic tensioners. With optimized production processes, we can significantly reduce lead times, ensuring that our customers receive their orders as quickly as possible. This means that we can provide a wider range of automatic tensioners to meet the needs of different applications and industries.

With 3 cutting lines and a Thermo welding machine for polyurethane belts of special lengths, we can offer a wide product range and fast delivery times.

Our new cutting area has been designed to meet the specific needs of our customers. With 3 cutting lines, we can offer a faster turnaround time for cutting power transmission belts. This means that our customers can receive their orders more quickly, allowing them to get their machines up and running with minimal downtime.

In addition to our cutting lines, we also have a Thermo welding machine for TPU belts of special lengths. This machine allows us to create custom-length belts that are specifically designed for our customers' needs. By offering this service, we can provide belts that fit our customers' machines perfectly, ensuring maximum performance and longevity.

One of the key benefits of our dedicated cutting area is our ability to offer a wide product range. With our cutting and welding capabilities, we can provide power transmission belts in a variety of materials, lengths, and widths.